For a while now I’ve been having a problem with the outfeed roller on my planer thicknesser. While thicknessing the machine will make a loud banging sound and the wood will fail to emerge from the machine. For a while I couldn’t figure out what was going wrong as everything visible seemed to be working fine. Eventually I decided it to run the machine for a while with some of the covers removed and it became immediately obvious the problem was the drive chain jumping on the outfeed sprocket.

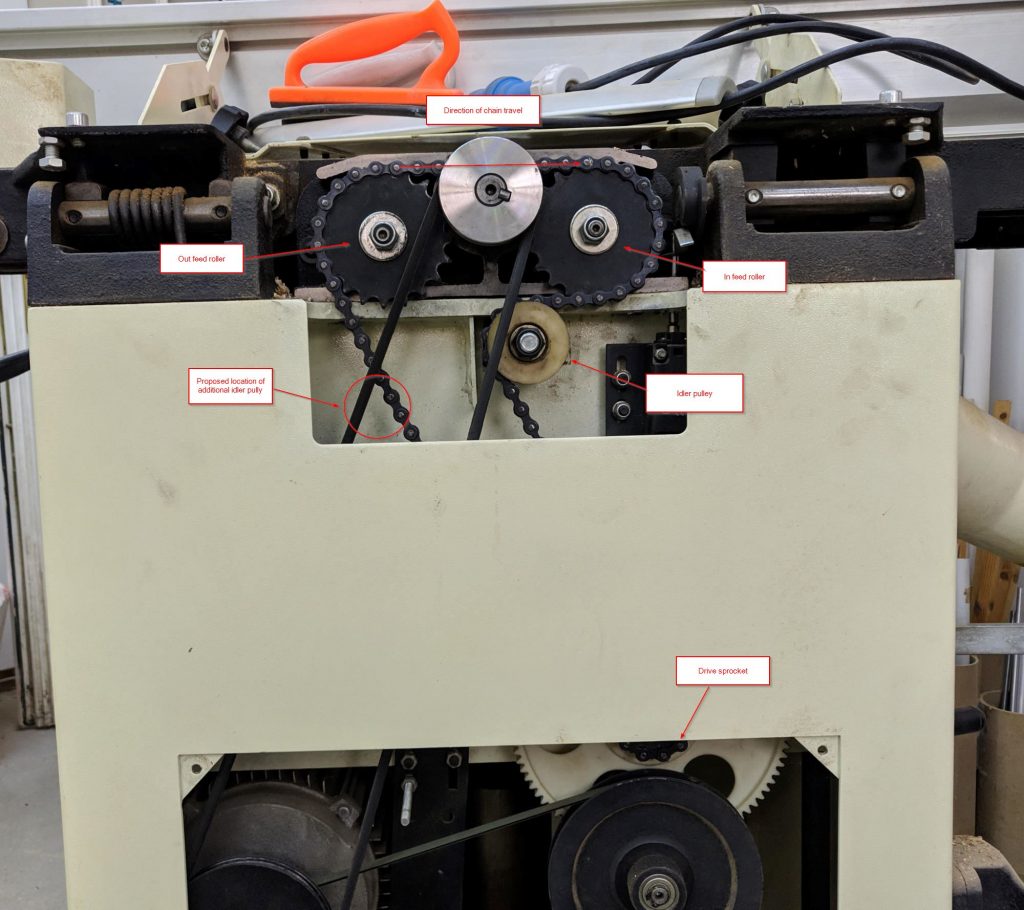

Obviously at this point I stopped the machine and examined the sprocket, it appeared to be fine. I then tensioned the drive chain as much as I could and ran the machine again, it still skipped. This machine has what I would consider a design flaw. The tensioning mechanism is on the return side of the chain which is, to the best of my knowledge, wrong. The return side of the chain will always be in tension because it’s being pulled by the drive sprocket. Additional tension is required on the feed side of the chain because that’s where it’s slack. To make things worse the outfeed sprocket only achieves about 90 degrees of engagement.

I’ve measured the chain as well as I can and these are the measurements I took. I’ve converted to imperial where it seems to make sense:

- Pitch – pin to pin centres – 12.7mm / 0.5″

- Roller Width – inside distance between roller plates – 4mm

- Roller Diameter – 7.65mm / 0.3″

- Plate Height – max – 8mm approx. 5/16″

- Plate Thickness – 1mm

- Pin Length – outside pin measurement – 9.55mm / 3/8″

- Pin Diameter – 3.55mm

Finding a Chain

Some suppliers of chain (such as Bearing Boys) have filters that all you to enter the measured dimensions and the site will then find the closest matching chain. This took me to a BS standard chain made by Dunlop with the reference 083-1. The correct description for this chain is: narrow section simplex roller chain. Even though this is narrow section is still seems to be wider than the one on the machine. The specification for this chain is:

- Pitch – 12.7mm

- Roller Width – 4.88mm

- Roller Diameter – 7.75mm

- Plate Height – max – 10.3mm

- Plate Thickness – 1.4mm

- Pin Length – 11.95mm

- Pin Diameter – 3.96mm

The pitch and roller diameter are correct which I think are probably the most important measurements. The plate height is a little large but I think the machine has space for it. The width is surprising, this is listed as a narrow chain but it’s still wider than the one on the machine. I think, though, it’s close enough. Unfortunately this is not a common chain specification so it’s reasonably expensive and I can only buy a 5m box. Measuring the chain in the machine is tricky but it seems to be about 1.2m.

When looking for a chain tool it occurred to me that maybe the machine is using a bike chain. There are far more bike chain options than I expected but interestingly there’s a 4mm roller width but that seems to be for cargo bikes. Despite much searching I couldn’t find any of this cargo bike chain. I did find though that a bike chain is 1/2″ pitch so a regular chain tool should work.

For a chain tool I just bought a cheap and cheerful one off Amazon. It wasn’t at all clear what was a good option vs a throw away tool so there didn’t seem to be much point in paying a lot.

Fixing the Planer Thicknesser

long story short… the new chain was quite a bit bigger than the old chain, to the point where it wouldn’t fit into my chain tool. I was able to use a punch and a socket to open the chain though. The old chain didn’t appear to have much stretch to it but there was a little, well within spec I would say. After fitting the new chain the problem didn’t go away but thankfully there was just enough clearance so I didn’t need to take it back off! I discovered that the chain tensioner on the machine tends to jam just before it fully tightens the chain. Pushed properly home it seems to fix the issue. Overall the chain tensioning mechanism sucks.

Dripping oil into inside edges of the bushings seems to be enough lubricate them and should be done before every use.