A few months ago I was faced with the challenge of taking down an old extension before it fell down on it’s own. Although I’ve tackled small building projects before, like fitting a new doorway or building an internal wall, this was the first time I was tackling a project that you could really call building.

Although the extension (if you are wondering what I’m talking about I believe it’s called an addition in the US) was only a single story with a flat roof it wasn’t the usual height of 2.5 to 3m (8 to 10 feet). The lowest part had a roof height of 4m externally and the highest was over 5m (16 feet). Clearly there was no way this demolition could be tackled from a ladder so that meant scaffolding.

I spoke to a builder and they suggested getting a company in to erect scaffolding around the outside then climb up on the roof and strip the before taking the walls down – a fairly standard process. The problem I had with this was that neither of the two roofs on the building (yes, there were two) were in very good shape and I felt there was a real danger they would collapse if I walked around on them which at a minimum would damage the rest of the house.

The conclusion I came to was that it would be best to carefully dismantle the roof from inside the building a bit at a time balancing the load on the remaining timbers as best I could. Whether this was the best approach I don’t know but it worked well for me. For this task though I would need a mobile scaffolding tower and after looking at various commercial options I decided to build my own.

Health and Safety Warning

Working at height is dangerous; one of the most dangerous things people commonly do. I completed this job unscathed but I’m bordering on paranoid about accidents. If you don’t feel you can complete a project like this safely don’t even try. Homemade scaffolding is right up there with homemade rocket cars in the stupidity stakes.

Research

Before I even started thinking about the design of my homemade scaffolding tower I went away and researched commercial scaffolding towers so that I could see what features I liked and gauge approximate sizes / weights / costs / etc. I felt one of the most important aspects of this process was getting a feel for what size footprint I’d need in order to have a stable tower at the sort of height I was going to be working at. I freely admit that much of my inspiration came from the Youngmann Boss Climba range in the end.

In terms of pricing a single width Boss Evolution tower with a footprint of 840x1800mm and a maximum working height of 3.7m costs a minimum of £673 new from www.bossscaffoldtowers.uk.com and typically more like £800 or more from most suppliers. Second hand short towers are fairly uncommon but larger towers typically go for around £900.

A reasonable quality 5m DIY class tower can be bought for about £250. For example the 5m Super DIY tower by Loyal from aluminium-scaffoldtowers.co.uk is listed for £275.99. The problem with these towers though is a lack of strength – they are good for painting your windows and cutting your hedge but I wouldn’t trust them to handle heavy duty work.

Slot together steel pipe scaffolds can be bought second hand for almost nothing but they are exterior climb and really should be consigned to the annals of history.

One thing I quickly learnt to be careful about was working height. When a scaffold says the maximum working height is 4 meters that means the platform you’re standing on is going to be at 2 meters. They assume you are standing on the platform and you are able to work at up to 2 meters above that. I’m an average sized guy at 1.76m so that means working above my head to get the full listed height. When choosing a scaffold make sure that you can actually work at the given height.

Design

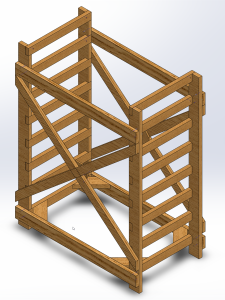

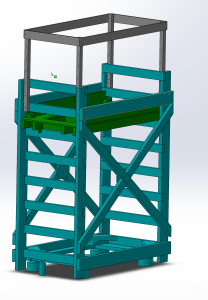

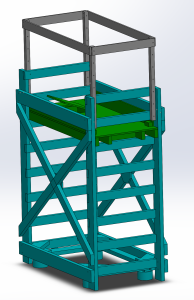

Before the start of any project I like to get at least a basic design drawn out so that I know I’m producing something that is going to be at least close to what I want. For this project I really went to town on the design because I wanted to be sure that I would feel safe climbing the tower.

I have a friend with SolidWorks and so I took this opportunity to start learning how to use it and got as far as producing some drawings. These are the drawings that I built the scaffolding from so I know it can be done but they aren’t exactly brimming with detail. I’m inclined to leave them a little vague though because you really should be thinking and understand this build if you are playing along at home.

Probably the most difficult aspect of the design was the guard rail system. I wanted something that would move up and down with the platform. Initially I designed it so that it was bolted to the platform but it turned out that wouldn’t work very well. In the end I bolted it to the legs of the scaffold and had adjustment holes. When I built the scaffold I wasn’t sure about the guard rail but it actually turned out to be amazingly configurable and a real plus point.

After about a week of spending every evening sitting at the computer I came up with a design I liked.

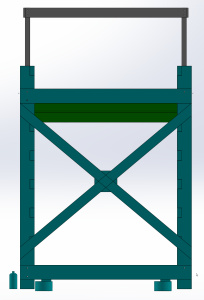

Homemade Scaffolding Tower Only

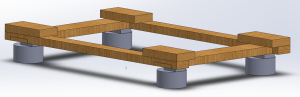

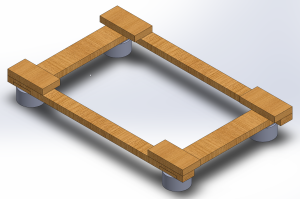

Homemade Scaffold Dolly

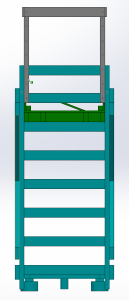

Homemade Scaffolding Guard Rail

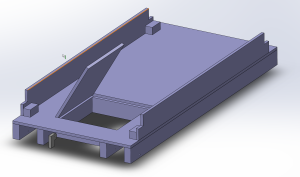

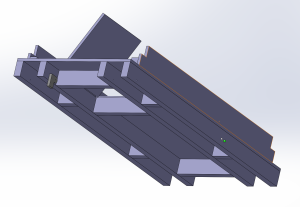

Homemade Scaffolding Platform

Homemade Scaffolding Complete Model

In part two of this series on building a homemade scaffolding tower I do some calculations on the platform to prove it will be strong enough and put together a parts list.