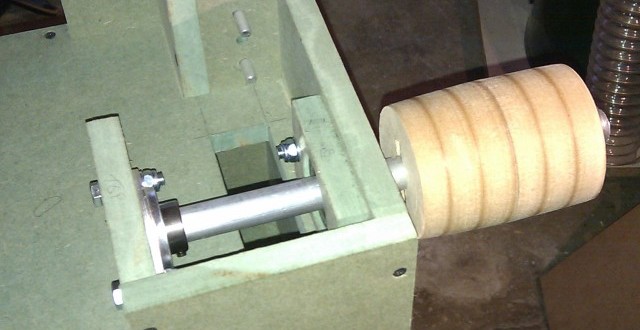

Now that the idler stock is complete I moved onto the drive shaft. I learnt a lot of lessons about make the roller from making the one for the idler stock and I managed to ignore most of them. The driven roller isn’t quite as crowned as the idler roller partly by design and partly because I messed up the reverse chucking.

So, I set about fitting the pulley to the driven shaft. I slipped on the pulley and the taper bush and then discovered I didn’t have enough space to get any allen key that I had that would fit the grub screws into actually to them up! I was just figuring out some fancy plan using pliers and a screwdriver head when the phone rang. Many thanks to mum for calling me because she prevented a deliberate error which can be seen in the image below.

Yep, I’d forgotten to put the belt over the pulley. I came very close to putting it all together only to have to take it all to pieces again. It was about this time, after I’d pick the case up a dozen or so times that I realized it was getting a bit heavy so I decided to cut a hand hold in the side. This provides for some ventilation for the motor as well so it plays a double roll.

And the hand hole in all it’s glory.