Before I got all carried away and did something all unnecessary, like spend money, I thought I should try hand routing some aluminium. The compound table is only £100 but that’s £100 I wouldn’t have to spend on something else in the build which is already costing too much anyway – why do I always pick expensive hobbies?

I knew that I had a piece of aluminum angle kicking about the workshop from when I built the belt sander (although I never actually used it in the belt sander build). I’d forgotten, however, that I also bought some aluminium sheet for that build as well (which I also didn’t use). The idea had been to make the table the belt runs on out of aluminium but it turned out that MDF with graphite at the edges worked fine so I never fitted the aluminium plate.

After much struggling to get the aluminium sheet out of its packing – I’ve never known something so well packed – I clamped everything thoroughly to the bench ready to try a little routing. I made sure I had no loose clothing, a full face mask, ear defenders and my wife standing by with a phone ready to call an ambulance (no joking). That might seem a bit excessive but I didn’t know how it was going to go. The router is an older model GMF 1600 and I wasn’t sure if it’d have enough power at 1600W but I thought it was worth a go. The straight edge I was following is a plasterers feather edge. It’s straight enough to most purposes and cheap enough that I didn’t mid if it got a bit damaged.

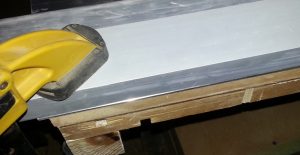

The aluminium is resting on some scrap MDF blocks to raise it up off the bench and it’s held down with four clamps which are done up tight enough that I’m happy the aluminium isn’t coming loose any time soon. The router bit is a top bearing “cheap and nasty” with a 1/4″ shank. The cutter portion is probably 1/2″ but I didn’t check and TCT. The cut was lubricated with WD-40 and the router was set to it’s lowest speed setting of 10,000RPM.

Everything I’d read about routing aluminium said to take very small cuts, people were talking about 0.25mm per pass but what I’d seen on the few videos I could find told me that some people were taking much bigger bites than that. In fact some videos showed people taking bites that I wouldn’t take out of wood. The problem with taking very light bites of 0.25mm or so is the difficulty in setting up the router. The preset steps on my router are fixed at 2mm and plunging by hand to 0.25mm accuracy is basically impossible. The router comes with an alternative base which allows more accurate depth control but that’s currently attached to the router table insert and I wasn’t about to take it off for an experiment. Rather than faff about I decided to trust my instinct and set up the cut to take 1mm at the full thickness of the aluminium.

The cut actually started at about 0.75mm and increased to 1.25mm as best as I could measure it on an aluminium sheet that is 3mm thick. That means the final portion of the cut is removing about 4mm3 of material in any 1mm of cut length.

I’m happy to say that I didn’t die trying this and the result was actually a resounding success as can be seen in the couple of photos here. In fact the only thing that could be considered less than perfect was the router bit which turned out to have a bearing a few microns smaller than the cutter which meant I routed the side of my feather edge a little as well. In one respect though I’m glad that the router bit ate some of my feather edge because it means I’m now sure that I’m able to take a quite sizable bite from aluminium without problem. The total height of the cut is probably around 20mm which matches the pieces I’m using for the CNC machine. The router bit is a good and sharp as it was when I started.

As for cut quality it’s nothing short of superb. I don’t know what grade of aluminium the sheet or the feather edge is but I’d guess the sheet is 5000 series and the feather edge something harder. The sheet has an almost mirror finish to the cut edge the feather board is smooth but would probably benefit from touching with a piece of sand paper. The router didn’t sound like it was straining and it was no harder than pushing though a dense hard wood, the sound of the cutt was different but that is probably because there is no grain in metal.

I used a fair bit of lubrication and I think I could get away with a lot less. There was no heat build up during cutting, the tool and the aluminium were both cool to the touch at the end. I’ve got another lubricating oil that I’m going to use next time that has Teflon included in it, as the cut isn’t getting hot I think it should do an even better job of easing the cut.