So there was quite a break between day one and two of this CNC build which was probably a mistake but nowt I can do about that now. After much debate my better half has convinced me to try building the CNC as my Christmas project. I’m planning on trying to get the mechanical side of the build completed by the new year which is when I have to go back to work – it’s early November at the moment which means I have about a month to design the machine and a month to build it. I reckon with some late nights and early starts I stand a reasonable chance.

I initially considered going for an MDF CNC machine mainly because it was cheap but some excellent advice from the guys on MYCNCUK saw that idea consigned to the bin in no time flat. If I’m going to spend an age building a machine I might as well build it properly! I then considered a wooden sub-frame with the CNC being aluminium extrusion but that just seemed like a poor compromise so I decided to switch to an all steel design for the frame.

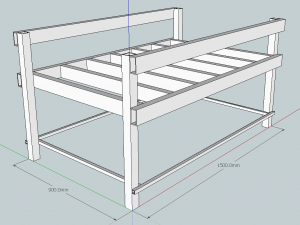

The X-axis rails and the bed are 80x40x4mm the legs are 50x50x4mm. The bracing around the bottom is 20x20x2mm. Overall, the X dimension is 1500mm the Y is 980mm (900mm leg to leg) and it stands 800mm tall. I believe this should give me a maximum possible cutting area of about 1400x800x200 which is a little more than I was initially aiming for.

The frame will, initially at least, be bolted together possibly with epoxy on the X-axis rails (inspiration from here: My First Router, Built in Steel – CNCzone.com). I would rather it was welded but I need to be able to dismantle the machine for moving in the future and I’m pretty sure I couldn’t get it down the stairs in one piece .

The current plan is to put the rails on the top of the X-Axis rail with the screw on the outside (there will be a screw on each side). To keep the length down I’m considering mounting the steppers on the bottom rail and using timing belts but I can’t help feeling that’s just complicating matters.

Now that I’m writing this and looking at the design again I think I’ll stick at least one vertical support from the bottom to top X-axis rail and add a bit of bracing. My gut is telling me it could do with some diagonal bracing but I want to keep the weight down if possible as this will be on an upstairs floor. The big question about this frame is regarding the straightness of steel box section. I’ve read a few posts that say it comes with a bit of a wobble on it and presumably it is necessary to mount the rails onto something that is fairly straight and flat.